Polishing and Sharpening a Japanese Sword’s Blade

After a blade is forged, folded, and quenched, it’s time to add its finishing touches. And while the Swordsmith takes care of the three steps from the previous phrase, adding these finishing touches to a custom Samurai sword is someone else’s job: the Togishi.

The Togishi’s job is a tedious one. It’s the longest, hardest work for creating an exquisite blade for any kind of sword. When the togishi is first handed the bare blade, it doesn’t look exquisite at all. Far from it.

While the forger takes care of creating the blade from a piece of metal, the Togishi is the one who truly reveals the blade’s inner beauty. He is the one who grinds, polishes, and sharpens the blade.

Coarse and Fine Grinding the Sword

When the Togishi first starts working on a blade, the first thing he does is grinding it with a grinding wheel and abrasive chemicals. The blade has to be grinded in order to remove all its imperfections and create the perfect shape.

Forging a blade isn’t an exact science – so the blade has many imperfections once it’s ready for the Toguchi. This is where coarse grinding the blade comes in, and is of paramount importance. Coarse grinding is done to remove the initial bumps and imperfections found on the newly-forged sword. It’s done with a harsher wheel and stones.

Afterward, fine grinding is used to reveal the finer details of the sword. It’s done with a finer grinding wheel and stone. Its goal is to prepare the blade for the next step: polishing.

Blade Polishing

Once the blade has its perfect shape and has been grinded thoroughly, it’s ready to be polished. This is where the Toguchi uses special stones to create the desired final effect: either a standard polish or a mirror-like polish.

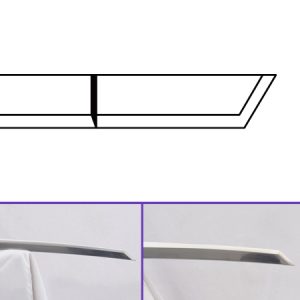

Once the blade is ground and ready for polishing, it still doesn’t reflect light in a perfect manner. If we put an object next to the blade, it will appear blurry. Hand-polishing the blade (as in our special process at Swords for Sale) then ensures the blade becomes mirror-like. Mirror polishing is perhaps the most beautiful one, as it creates a reflective blade which is also of the highest quality. If we put an object next to it, it will be reflected in a beautiful manner and not be blurry.

Moreover, the Toguchi can use special stones in order to further accentuate the sword’s beauty. These are called “Hazuya” and “Jizuya” stones, and their use creates true works of art out of what might otherwise be normal blades. They’re used to create a “matte”, beautiful effect on any kind of blade which has a clay-tempered hamon.

At Swords for Sale, we can use these stones to create many types of blades, and they look incredible on all Clay-Tempered blades. You can see the image below to see why Hazuya and Jizuya polishing creates such exquisite blades, leaving them “whiter” than before. We also have a secret, very costly process which creates even more beautiful blades, and takes very long for our Togishi to create.

Sharpening

When considering a blade’s sharpness, we have to think on multiple levels. When the Toguchi sharpens the blade, he does so for certain very precise goals. Thus, the toguchi first considers what the blade will be used for.

- If the blade is a bokken or used for martial arts practice, it can remain Unsharpened and raw.

- If it will be used to cut through objects, the Toguchi hand-sharpens it with a special 13-step process and obtains a razor-sharp blade.

- If the blade has to be used to cut repeatedly through multiple, harder objects, he uses a special Niku stone to sharpen the blade even more – and make it ready for the harshest of cuts.

If the blade needs to be sharpened, the Togichi first sharpens the whole length of the blade. Afterward, he uses a special piece of cardboard along with fine sandpaper to sharpen the blade’s tip, also called the Japanese sword’s Kissaki.

The procedure of sharpening a knife hasn’t changed much since feudal Japan. To acquire a sharp edge, the blade is still sharpened using a whetstone, and the whetstone will basically fall off a little piece of the blade. Millstones are often as precious as swords nowadays. According to the research, high-quality grindstones can fetch thousands of dollars from expert sword collectors and swordsmiths.

When sharpening a katana’s blade, rough, low-grain grindstones are first used, and then finer, higher-grain grindstones are gradually introduced. Of course, this is the same approach that is employed today when honing any blade.

What is sharpness?

When considering whether a blade is sharp or not, we have to consider what the blade will be used for. Sharpness doesn’t exist in a vacuum, and different blades are used for different purposes.

Whereas a razor can cut through a beard well, it cannot cut a tree. While a sword can cut through a tree well, it cannot cut through armor and helmets. What is important to look at is both the sharpness of the blade and the thickness of its cutting edge. A great blade has to be sharp enough, but also hard enough at its cutting edge. This is because a blade has to cut through harder objects all the time, unlike a razor.

The best blades are hard enough, but not too hard. If they’re too hard, they can become brittle. Cutting edges that are too hard will occasionally break. A cutting edge that is a little bit milder is tougher, but again, too mild and the edge becomes weak. Because of this, a blade’s cutting edge hardness is crucial. It is dependent upon the steel’s quality and the hardening process (heat treatment and clay-tempering).

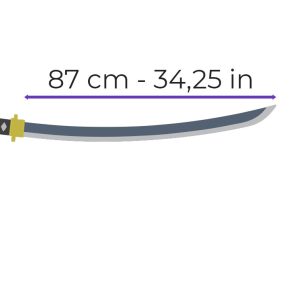

Sharpness is also related to the blade’s form and curvature. A significantly curved blade is sharper than a straight blade when cutting by a swinging motion – especially laterally. Therefore, curved Japanese swords are sharper and more useful on a battlefield than straight swords.

Sharpness therefore depends on the sharpness of the blade and the thickness (hardness) of its cutting edge, but also its heat-process and blade curvature.